DISCOUNTED EDUCATION PRICING! CALL 1-877-891-8411. We Gladly Accept School Purchase Orders!

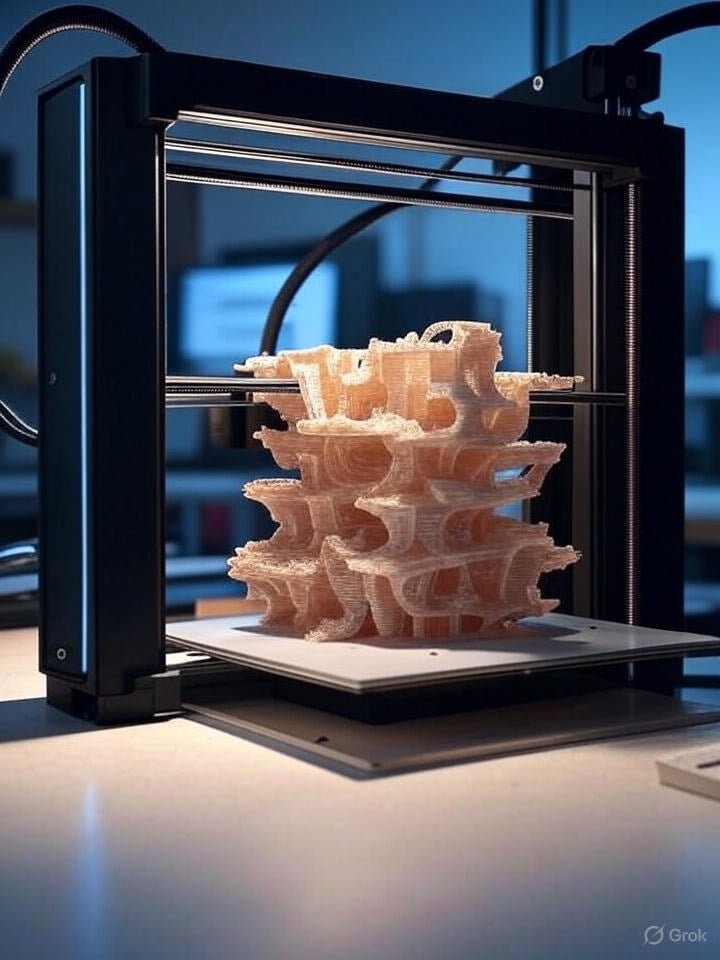

3D printing, also known as additive manufacturing, has transformed from a niche technology into a cornerstone of modern innovation. By 2025, 3D printing is revolutionizing industries, from healthcare to aerospace, by enabling rapid prototyping, customized production, and sustainable manufacturing. This comprehensive guide explores the latest advancements, practical applications, and future trends in 3D printing, offering insights for beginners, hobbyists, and professionals alike. Whether you’re curious about how 3D printers work or seeking the best 3D printing solutions for your business, this article is your go-to resource for mastering the art and science of 3D printing.

3D printing is a process of creating three-dimensional objects from digital designs by layering materials such as plastic, metal, or resin. Unlike traditional manufacturing, which often involves subtracting material (e.g., cutting or drilling), 3D printing builds objects layer by layer, offering unparalleled flexibility and precision.

Each technology has unique strengths, making 3D printing versatile for various applications.

In 2025, 3D printing is no longer just a prototyping tool—it’s a mainstream manufacturing solution. Here’s why it’s transforming industries:

3D printing enables bespoke designs without the high costs of traditional manufacturing. From custom prosthetics tailored to a patient’s anatomy to personalized consumer products like shoes or phone cases, the ability to produce one-off items is unmatched.

Designers and engineers can iterate quickly, printing prototypes in hours rather than weeks. This accelerates product development cycles, saving time and costs.

Additive manufacturing minimizes material waste by using only what’s needed for the build. Additionally, 3D printing supports biodegradable materials and localized production, reducing the carbon footprint of shipping.

Unlike traditional methods requiring expensive molds, 3D printing is ideal for low-volume production, benefiting startups and niche markets.

3D printing can create intricate designs impossible with conventional manufacturing, such as lightweight lattice structures for aerospace components or internal channels in medical devices.

The versatility of 3D printing has led to its adoption across diverse sectors. Here are some of the most impactful applications:

Choosing the right 3D printer depends on your needs, budget, and expertise. Here are some top picks for 2025:

The choice of material impacts the strength, finish, and application of 3D-printed parts. Common materials in 2025 include:

As 3D printing evolves, several trends are shaping its future:

Artificial intelligence is enhancing 3D printing by optimizing designs, predicting print failures, and automating workflows. AI-driven software can suggest material choices and improve print efficiency.

Advanced printers now combine multiple materials in a single print, enabling complex, multi-functional parts like electronics with embedded circuits.

Construction and aerospace industries are adopting large-scale 3D printers for buildings, bridges, and aircraft components, reducing costs and construction time.

The push for eco-friendly manufacturing is driving innovation in biodegradable and recycled materials, such as algae-based filaments.

An emerging field, 4D printing involves materials that change shape or properties over time in response to stimuli like heat or moisture, with applications in robotics and medical devices.

Select a printer based on your budget and goals. Beginners should start with an affordable FDM printer like the Creality Ender-3.

Familiarize yourself with CAD tools like Tinkercad (free, beginner-friendly) or Fusion 360 (professional-grade). Online tutorials on YouTube or platforms like Udemy can help.

Download free 3D models from repositories like Thingiverse or MyMiniFactory. For custom designs, hire a designer or learn to create your own.

Start with simple prints to understand your printer’s capabilities. Adjust settings like temperature and speed to optimize quality.

Engage with 3D printing communities on Reddit, Discord, or X to share tips, troubleshoot issues, and stay updated on trends.

Despite its advantages, 3D printing has challenges:

3D printing in 2025 is a dynamic field driving innovation across industries. From personalized healthcare solutions to sustainable construction, its applications are vast and growing. By understanding the technology, choosing the right tools, and staying informed about trends, you can harness the power of 3D printing for personal or professional projects. Start exploring today, and join the additive manufacturing revolution!